What is an IBC Tank?

A General Introduction to IBC Tanks

What is an IBC Tank?

An IBC Tank, short for Intermediate Bulk Container, is a standardized container designed for easy transportation and shipping. It is suitable for transporting and handling solid and liquid hazardous materials but is not appropriate for high-pressure gases. IBC Tanks can be loaded and unloaded using forklifts, allow for multi-layer stacking, and make it easy to measure both the usage and residue of contents. Additionally, they offer the advantage of being reusable, contributing to cost efficiency and sustainability.

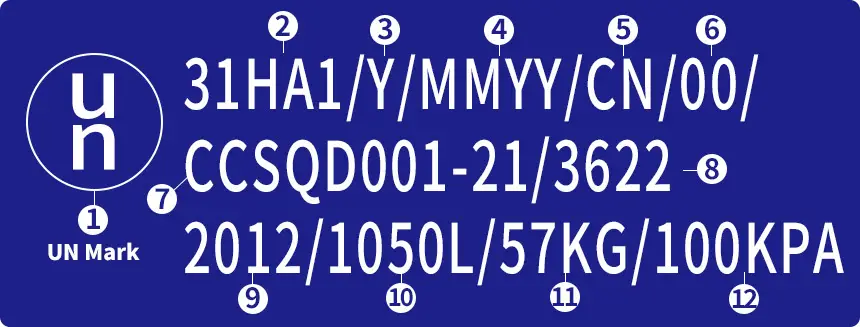

How to Read Export Container Markings

Here’s the meaning of the UN mark and other characters typically displayed on export containers

1.UN Packaging Symbol

2.Material and Structure

3.Approved Packaging Grade

4.Date of Manufacture (MM-DD-YYYY)

5.Country of Manufacture

6.Manufacturer Code

7.Certification Body

8. Stacking Test Load (kg)

9. Maximum Permissible Gross Weight (kg)

10. Capacity at 20°C (L)

11. Net Weight (kg)

12. Test Pressure

Advantages of IBC Tanks

01

Maximizing Utilization of Storage Space

When using the same surface area, an IBC tank can store 4,000L compared to 2,400L when using drums. This significant capacity advantage makes IBC tanks the preferred choice for efficient storage and transport.

02

Ease of Operation During Filling and Discharge

Compared to five 200L drums, which take 90 minutes to discharge, an IBC tank can discharge 1,000L in just 15 minutes.

03

Significant Reduction in Transportation Costs

To transport 16,000L using drums, 80 drums are required. In contrast, using IBC tanks allows for the transportation of 18,000L with only 18 tanks, offering greater efficiency and cost savings.

04

Efficient Transportation

While drums require wrapping on pallets, IBC tanks offer the advantage of not needing wrapping, simplifying the process and enhancing efficiency.

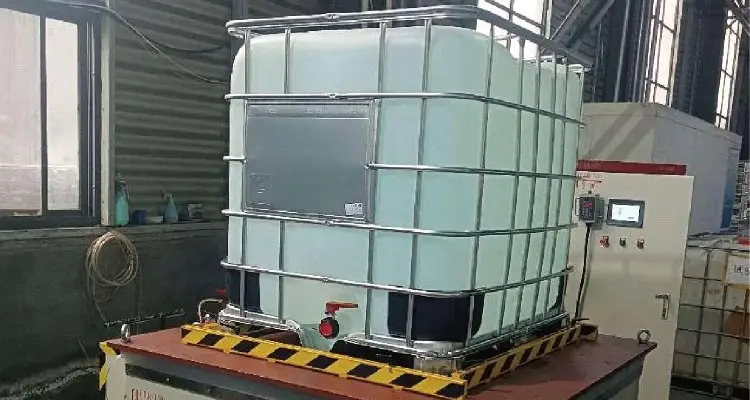

IBC Tank Product Testing

Vibration Test

Fill the IBC tank up to 98% of its maximum capacity with water and place it at the center of the testing bench. If there is no leakage, bursting, or damage to structural components, the product is considered qualified.

Lifting from the bottom

Fill the IBC tank with water (1,000L) and add supplemental weight up to 125% of the maximum allowable gross mass. If there is no leakage of contents and no permanent deformation that affects safe transportation, the product is considered qualified.

Stacking Load

Place the IBC tank on a flat surface and proceed with stacking during transport. If there is no leakage, and no deformation to the intermediate bulk container, including the contents and the bottom pallet, the product is considered qualified.

Leakage Test

Close the vent, pressurize the container to 20 kPa using a compressor, and spray soapy water on the surface. Maintain the pressure for 10 minutes. If no bubbles form on the surface, the container is considered qualified.

Water Pressure Test

Close the pressure relief device, fill the container with water, and connect a pressure gauge to a pressure pump. Maintain a pressure of 100kPa for 10 minutes. If there is no leakage or deformation, the container is considered qualified.

Drop Test

Fill the IBC to 98% of its capacity, add antifreeze, and subject it to low-temperature treatment at -18°C. Drop the container from a height of 1.9 meters. If there is no leakage of contents after the impact, the container is considered qualified.